Farming is a more dynamic industry than the average person might think! Our goals are to grow the healthiest food we can, while considering our impact on the environment and on future generations. This will never change. However, the food industry does change all the time, which means we have to grow and change along with it.

Always at the forefront of a farmer’s mind are efficiencies – how can we increase the amount of food we grow without compromising the top-notch quality we are known for? How can we get all the work done with a limited amount of people? In times of high demand, how can we go faster? How can we reduce the amount of food waste in our production? How can we prevent crop failure? How can we do all of this without spending more than we make?

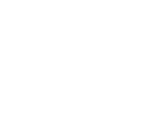

This is where Wolfgang shines. He’s always thinking a few steps ahead, and if you ask the right questions you will find he’s always got ideas brewing. Where there is a will and a Wolfgang, there is a way! His approach is very hands-on and his goal is to constantly search for new ways to improve the already well-oiled machine that is Pfenning’s Farms. He finds those ways by being right in the thick of it – whether it be in the fields, in the shop, or in the office talking about sales trends and shifts in the organic industry. Here at Pfenning’s, our mindset is open. We do what we do how we are doing it for the moment, but ideas and experiments are most welcome. We’re always willing to try something new – even though it may not work out. As the upcoming younger generations take their places on the farm, it’s gratifying to see this spirit of continuous improvement carry on. There’s always a better way – we just haven’t thought of it yet!

Always Something On the Go

The shop out back is never quiet, there’s always a project on the go. Maintenance, repairs, and modifications are ongoing here. Farm equipment is a major investment, and mechanical expertise and aptitude is very handy to have! We are fortunate that there are many here who have these crucial skills. This year for example, our transplanter was modified to add two extra rows. Now, instead of planting 4 rows at a time, we can plant 6.

Over the years there have been many things tried and abandoned – but we have learned something from each of them that helped us move on to something better. (Or sometimes, to revert back to the tried-and-true.)

When the double-row seeder became available, the potential seemed clear – instead of a single row of spinach, almost twice as much could be grown in the same space. The carefully tended land should have provided plenty of nutrients for all the plants, and the spacing was thought to make it more difficult for the weeds to take over. In reality however, the density of plants was too high – there was not enough airflow and disease issues resulted. Also, there was not enough room for people to harvest comfortably. The yield ended up roughly the same, while our costs (mostly for seeds) had increased significantly.

The picture below shows an early attempt at improving on the hoeing process. The team laid across this platform pulled by a tractor, using tiny hoes to pull weeds. It was hoped that this would increase our efficiency, but the opposite turned out to be true. Machines love uniformity, but in reality, people are very different. The faster and stronger weeders were slowed down by this process, and the slower ones couldn’t be as thorough and missed things. Soon after this was attempted, it was given up – not as a failure but as a good try. And we learned something important. Each person brings unique strengths and value to a team. When we tried to make everyone the same, things fell apart pretty quickly.

Continuous Improvement

In the 80’s and 90’s when the farm was much smaller, operations were very small-scale with limited machinery but the family and existing staff could manage the demands quite well. Over the years as the farm business grew, our production needed to grow as well. This required more storage, more production space, and more equipment.

One of the biggest challenges was the carrot line. For a long time it was changed every single year to improve efficiency and output. One year we even put a line through the window so that we could have more people on the carrot line to be able to get through all the carrots we needed to process. Make it happen no matter what it takes – that’s the attitude!

When the farm decided to expand with local partnerships and the import program, the need for a much larger warehouse became apparent. Different produce requires different temperatures and humidity levels, so many storage rooms were required. We use a heat reclaim system on the farm to efficiently manage the temperatures in the warehouse and throughout the rest of our buildings. This means that some of the heat generated from our refrigeration system is captured to heat up water, which in turn warms the loading dock, production area, office etc. There’s even enough to heat the water in the closest bunkhouse. Efficient and environmentally friendly too! How cool is that?

Ongoing Commitment to Organic Standards

Being committed to being organic will always present new challenges that non-organic farms don’t have to face in terms of pests and weeds. Here on the farm we are always open to trying new methods that support our organic standards while increasing our output and efficiency.

New technologies to help us with the backbreaking work of weeding have been very welcome. Have you ever seen the flamer in action? This is an attachment that is pulled by a tractor, that is designed to burn weeds that are growing between rows. This must be operated with great care and precision, and the end result is worth it. We can get rid of a lot of weeds very quickly this way! We do still rely on large hand hoeing and weeding teams when the plants are particularly vulnerable in their infancy. A machine cannot replace the keen eye of a person in this case.

In Harmony With Nature

Of course, the healthier the plant, the easier it is for that plant to resist pests and disease. We have found that inoculating our transplants with mycorrhiza really gives our plants a step up with this. Mycorrhiza fungi is a vital part of the soil ecosystem, and forms a symbiotic relationship with green plants. The fungi take up water and minerals from the soil and deliver them to the plant; and in turn the plant provides “food” to the fungi through photosynthesis. Where healthy soil is present, most crops develop this relationship naturally; inoculations ensure a healthy start to the growth cycle.

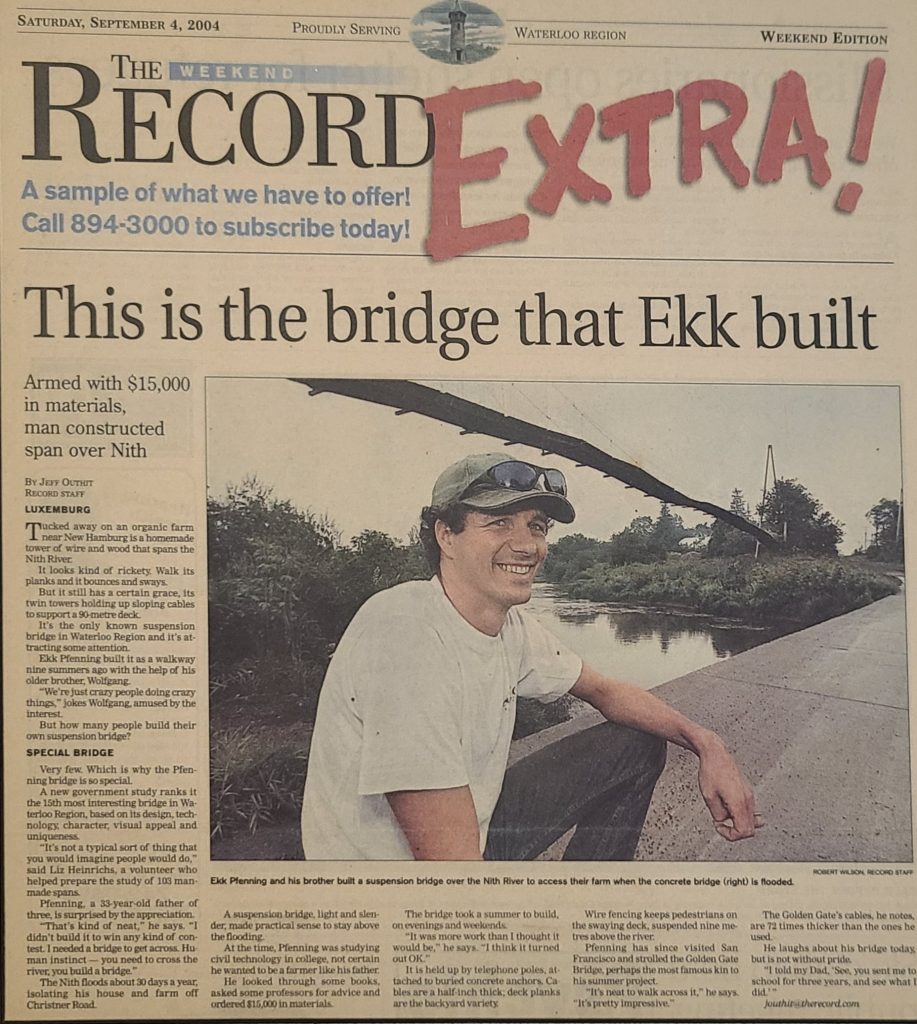

Normally a pretty piece of our landscape, the unpredictable Nith River runs through the farm. When the riverbanks overflow (as they do every year without fail), parts of the farm are cut off from the rest, including the home of Ekk and Jenn Pfenning and their sons. Tired of being isolated every time the river flooded and fresh out of school with a CET Civil Engineering diploma, Ekk designed a walking suspension bridge across the Nith and built it with Wolfgang. This was remarkable enough to make the news at the time; but to the Pfenning brothers it was just something that needed to be done.)

Looking Ahead

As we work towards a better tomorrow, we look forward to seeing what the next years will bring. The next generation will face their own challenges as the world keeps changing, and we are confident that they will continue in the same spirit that drives us now. The desire to make the world a better place for all, now and in the future; and an openness to seeing and doing things differently without compromising our treasured values.