Why Do You Need a Grain Mill?

Most supermarket flours and cereals have been ground weeks or months before they are used. When wholegrain is cracked, rolled or milled, the grain begins to oxidize rapidly within hours leaving grains to become stale, rancid and potentially mucous forming. In most whole foods, herbs, spices and seeds, the nutrients remain dormant until cracked. Once ground the volatile germ oils, enzymes, and vitamins are released with an aromatic flavour and freshness.

Ideal for the home baker, these mills will grind most dry grains including, wheat, barley, oats, rice, spelt, rye, millet, buckwheat, various lentils & soy beans. The F100 will also grind whole maize and chickpeas. SAMAP flour mills produce the finest of flour in your own kitchen, at your own convenience.

Did you know:

- Whole grain is a good source of dietary fibre, protein essential fatty acids, B-complex vitamins and vitamin E.

- The outside layer of the grain kernel, called the husk, is composed mostly of fibre and minerals. Insoluble fibre passes through the body undigested, cleaning the digestive tract by 'sweeping' harmful deposits from the body. This function may be a significant help in preventing heart disease and cancer. The soluble fibre present in grains slows digestion and allows optimum absorption of nutrients, such as natural oils and carbohydrates.

- The germ is full of highly unsaturated fatty acids, as well as vitamin E, which acts as a highly effective anti-oxidant.

- Unfortunately, the oils and unsaturated fatty acids are very volatile and begin to oxidize and turn rancid almost immediately after grinding. Rancid oils contain free radicals which have been connected to heart disease and other degenerative diseases. Free radicals are also formed when grains are milled at high temperatures, commonly occurring with metal grinding mechanisms.

We sell SAMAP Mills which use a grinding stone made of NAXOS BASALT embedded in stabilized Magnesite. This means a 100% natural grinding stone which through its design does not require sharpening even after years of continuous use.

All SAMAP Electric Models employ a patented cooling turbine which keeps the grinding stones and flour cool even in continuous use applications.

Pfenning's is the Canadian Importer and distributor of SAMAP Grain Mills. We carry four models of SAMAP Mills and The Marcato Marga.

Our Models

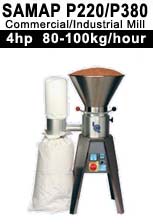

P 220/380 Commercial/Industrial Mill

The Commercial SAMAP mill is outstanding for its throughput and its ability to produce a really fine flour. It was developed especially for these qualities. (Genuine stone milled flour is light and fluffy). It makes the production of all bakery and pasta goods, using wholemeal flour possible.

The mill is solidly constructed. The mill stones are made up of natural stone components and are extra hard and should not need to be re-dressed. They are nevertheless easily replaceable. The mill housing is made up of anodized aluminum.

The 3000 Watt 4 HP motor runs on 3 phase, 220 or 380 Volts. It is protected by a cut-out switch. An ampere meter allows control for the optimum performance setting (maximum throughput with a given desired fineness of flour). The adjustment for a variety of grist is simply done by turning the upper part of the mill.

The feed rate from the hopper is completely adjustable.

Technical data

- Millstones

- Extra hard natural stone (NAXOS Emery) is embedded in stabilized magnesite cement. The stones hardly wear at all in use but are nevertheless simple to change. They match each other perfectly being ground in at the factory. They do not need to be re-dressed at all.

- Diameter of the stones: 200 mm (approx 8″).

- Turning speed 2800 RPM.

- Grain in-feed: The grain falls by its own weight through the fixed upper mill stone into the milling chamber between the stones. An agitating spindle projects through the inlet opening to prevent clogging or bridging of the grain. The inlet opening is adjustable is size, being varied to adjust for different grain sizes and different flow speeds required. The Commercial SAMAP mills all kinds of grain and also dried peas and maize. Oil seeds cannot be milled.

- Regulation of degree of fineness: Infinitely variable from very coarse to very fine by simple turning of the upper part of the mill. A locked screw holds the setting at the chosen degree of fineness.

- Flour ejection: The flour is carried out of the milling chamber by a strong stream of air which also cools the mill stones. The flour passes through a special casting which separates the flour from the air.

- Mill performance: The finest setting, which is suitable for the production of confectionery as well as bread, 80/100 kg per hour (200 kg/h when using coarsest setting).

- Mill chamber casting: Aluminum in food quality – particularly hard through deep anodizing which gives the grey colour.

- Hopper: 40 kg approximate wheat capacity.

- Motor: 220/380 V 3 phases with ampere meter, 3000 Watts, 4 HP – protection cut-out switch. This is standard equipment. For all other special equipment required, please contact us.

- Dimensions and Weight:

- Height: 135 cm

- Width: 85 cm

- Depth: 60 cm

- Weight: 74 kg (approximately)

HI 220/380 Commercial/Industrial Mill

This solidly constructed SAMAP commercial mill is noted for its outstanding output and its ability to produce a really fine flour. It was developed especially for these qualities. (Genuine stone milled flour is light and fluffy). The mill stones are made up of natural stone components and are extra hard and should not need to be reset, however, are easily replaceable. The mill housing is made up of anodized aluminium.

The 4000 Watt 5.5 HP motor runs on 3 phases and is protected by a cut-out switch. An ampere meter allows control for the optimum performance setting (maximum output with your choice of desired fineness of flour). The HI 380 can be adjusted for a variety of grains by simply turning the upper part of the mill. Use this mill to create wholemeal flour for the production of all bakery and pasta goods.

Guarantee: 2 years

Technical data

- Millstones: Extra hard natural stone (NAXOS Emery) is embedded in stabilized magnesite cement. Stone wear is minimal, but they are nevertheless simple to change. Factory ground in, they match each other perfectly. Diameter of the stones: 200 mm. Turning speed 2800 RPM.

- Grain feed: The grain falls by its own weight through the fixed upper mill stone into the milling chamber between the stones. A shaking spindle projects through the inlet opening to prevent clogging or bridging of the grain. The inlet opening is adjustable in size for different grain sizes and different flow speeds required. The commercial SAMAP mills will grind all kinds of grain including dried peas and maize. Oily seeds cannot be milled.

- Regulation of degree of fineness: Infinitely variable from very coarse to very fine by turning the upper part of the mill. A locked screw holds the setting at the chosen degree of fineness.

- Flour ejection: The flour is carried out of the milling chamber by a strong stream of air which also cools the mill stones. The flour passes through a special casting which separates the flour from the air.

- Mill performance: The finest setting, which is suitable for the production of confectionery as well as bread, grinds 120 kg per hour (200 kg/h when using the coarsest setting).

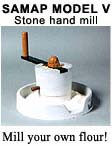

Model V Stone Hand Mill

Simple and robust, easy to use, it will give you good service. SAMAP flour mills are designed to last 25 years or more. In order to allow for people of very different physical strength to use the mill and to keep this physical strength to a minimum, SAMAP have built in double roller bearings which run on a stainless steel (rustless) vertical spindle, the lower part of which is embedded in the base.

The Mill Design

The grain is contained in the upper rotatable millstone and the milling is done by simply turning the handle. The grain is forced between the two stones and the flour comes out of the sides in the collecting trough. The dark knob regulates the rate at which the grain flows from the hopper to the mill stones and also the amount of effort needed for every revolution. The knob at the top controls the gap between the stones and hence the fineness of the flour.

PRODUCTS THAT CAN BE MILLED

These include hard dry cereal and pulses, rice, wheat, rye, oats, barley, and buckwheat. It is also possible to produce oat flakes by milling de-hulled or hull-less oats on a fairly coarse setting. However, the stones may smear somewhat. A condition easily repaired by grinding a small amount of rice to clear the smearing material from the grinding surface. For high quality trouble free flakes from any type of grain including oil seeds though, see the Marcato Marga below.

SPECIFICATIONS OF SAMAP Model V HAND MILL

- Stones: A natural stone (NAXOS BASALT) bound in a magnesite cement.

- Wear and Tear: Insignificant – so the grinding surfaces do not require re-dressing.

- Performance: 30/80 grams per minute depending on:

- setting for the fineness of the flour

- the cereal being milled

- the position of the in-feed adjustment

- the speed of rotation

TECHNICAL DATA

- Diameter at base: 280 mm

- Overall height: 350mm

- Height without clamps: 265 mm

- Height of stones: 150 mm

- Maximum opening of the fixing clamps: up to 6 cm

- Weight: 8 3/4 kilograms

SAMAP Kneader

Home bakers love this simple kneader, the ideal companion of the grain mills. Kneading can be tiring and time consuming, but is an important feature of bread making: flour particles are completely hydrated and air is incorporated in the dough, helping the fermentation process and giving more resilience to the baked product, with a finer and more uniform texture.

The mixing bowl is a 17 litre thick sandwich bottomed stock pot. The geared motor and dough hook assembly is clamped onto the pot without difficulty. You now have a small professional machine capable of mixing from 1 to 8 kg of dough – moist or firm – in a few minutes. Even the thickest rye dough is ready in just 10 minutes.

Once your dough – yeast-raised or sourdough – is kneaded, you can simply leave it in the stainless steel pot, remove the kneader head, cover it with the supplied lid and put in a warm place.

The SAMAP T200 Kneader is driven by a robust industrial motor and a planetary gear reducer. For cleaning and storage, the kneading hook disconnects easily. It is a perfect machine: simple and safe to use, easy to clean, maintenance-free and compact.

Guarantee: 2 years